You Scan Me Right Round

In my first post about 3D scanning, I showcased the Chickering pin block; you can view that post here. Today, the subject of the 3D scan is the cast-iron plate from the same piano. The cast-iron plate holds the strings in place with hitch pins at the bottom and allows the tuning pegs to pop through the top. The scan helps inform the 3D model of the pin block created earlier because the pin block’s shape perfectly contours the shape of the cast-iron plate.

What’s Your Sign? I’m a LEO

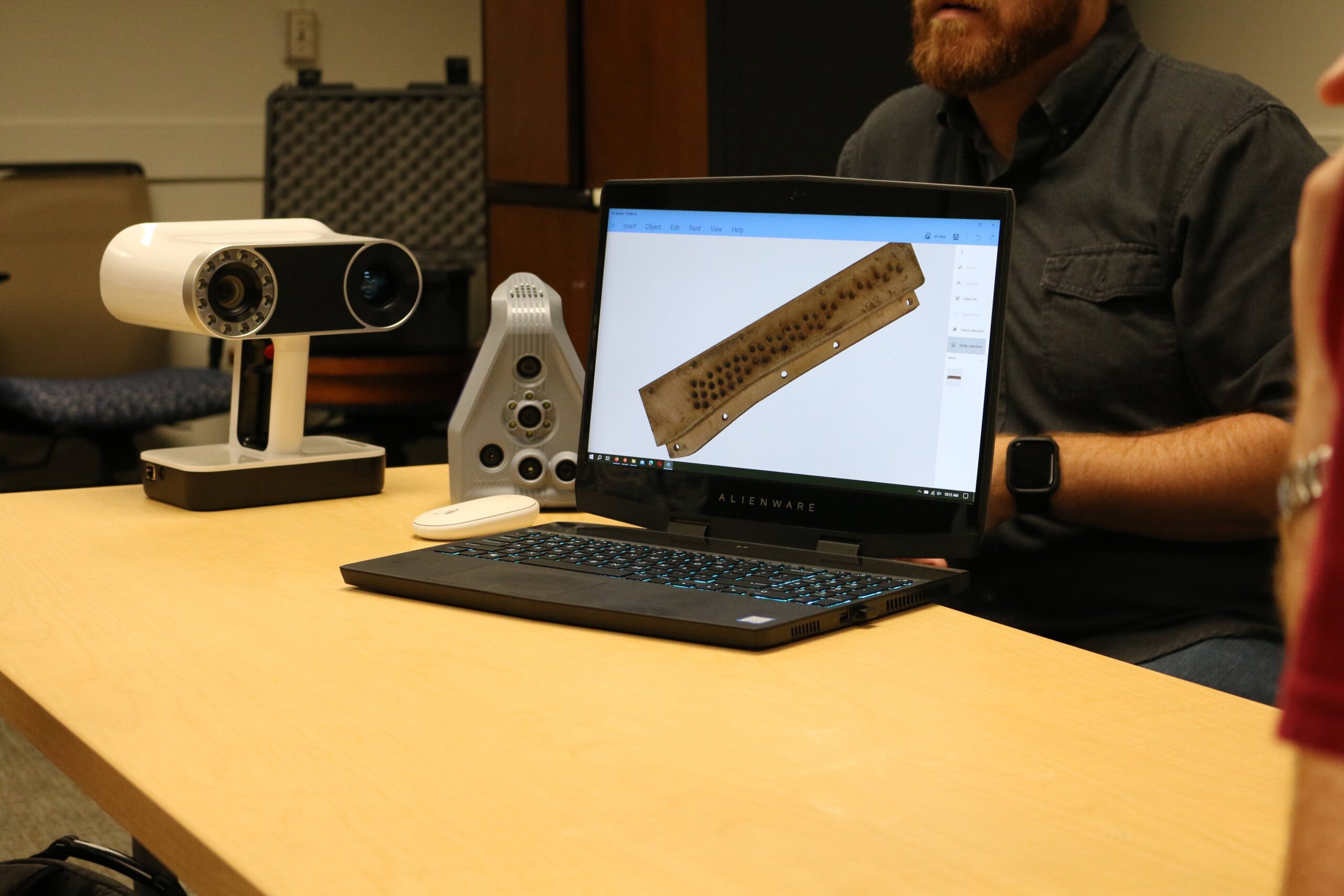

Since this subject is much larger, the Artec LEO was the tool of choice for the task of scanning. The scanner fires light strobes that correspond to a “known, fixed-grid” in space. The cameras read the differences between the fixed-grid and the actual data being read to generate the 3D model. Because of the plate’s size, the fine detail of the Artec Space Spider scanner is unnecessary.

Scan Calls Are the Worst!

The scans are done while the plate is suspended on a specialized plate cart. The scans will also pick up the cart and be removed later when the scans are put into 3D modeling software (pictured below). I’ve never seen the bottom side of a piano plate and was impressed with how the pin blocks fit perfectly to the contours of the casting. I thought “pin block” – and that it was a square block that held the pegs. I had no idea they were so shaped, and I imagine the registration of those shapes adds to the stability of the structure.